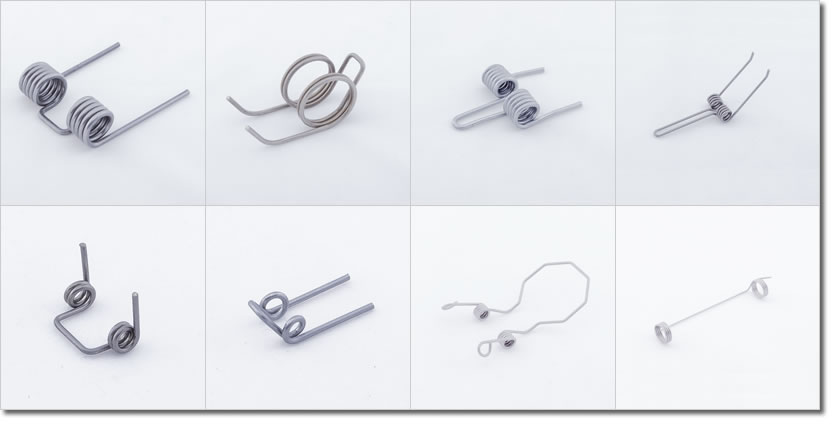

Double torsion springs

Double torsion springs for optimal power distribution

In order to achieve optimum distribution of forces on torsion springs with torsion and torsion springs, double torsion springs are used.

In the production of these technical springs one leg is connected to the other, so that a symmetrical shape results.

Double leg spring with inside or outside ends

Reiner Schmid Produktions GmbH produces on your behalf double torsion springs in a wide range of possible designs.

So you will find the right double leg spring for every project and every place of use.

In most cases, the ends of the legs lie on the outside of the spring body. Finished leg ends on the inside are more elaborate, using our unique modern manufacturing techniques However, it can be easily realized for CNC bent wire parts.

Our team is flexible to your wishes and realizes the special features that the ordered double torsion springs have to be ready. Thanks to state-of-the-art technology, we can implement almost any type of double leg spring.

The right double leg spring for every need

You need a double leg spring in a specific shape, size and wire size?

That's no problem for us as a manufacturer.

Contact us and send us the specifications for your double leg spring!

We are happy to provide you with samples and prototypes before we start the actual series production - so you can check the correct fit of the double leg spring and give us new dimensions if necessary. Timely optimization saves us time-consuming reworking.

We make technical double torsion springs usually drawn from spring steel wire (1.4310 or patented in the variety classes SM, SH, DH), you can also offer the following materials after consultation:

- spring bronze

- brass wire

- Inconel

- Nimonic

- titanium wire

- iron wire

Technical double torsion springs are our profession

Talk to the experts of Reiner Schmid Produktions-GmbH today if you are in need of sophisticated, highly resilient and under all circumstances reliable double torsion springs! We are the right contact person for every sturdy double leg spring you need.

Even if you are not sure how your double thigh springs designed in detail, you are right with us. We are happy to advise you individually, taking into account our many years of experience. We are happy to help you too at the planning and design of the double leg spring aside.

Especially if you need double torsion springs with special features, you should not rush the series production.

A prototype pays off here, as it allows you to take a look at the accuracy of fit and functionality in advance. Often, small improvements are enough to achieve significantly better results.

Benefit from our perfectionism and individual advice from our experts.

Request a free quote now: Tel.: 004921238241873

Request a free quote by email now

Reiner Schmid Produktions GmbH Specialist and expert for the manufacture, production, production, development and sample production of torsion springs, double torsion springs and bent wire parts.

Abstract:

The manufacture, production and production of torsion springs, double torsion springs and bent wire parts is carried out in small series, large series and variant production.

The calculation, development and testing of torsion springs, double torsion springs and bent wire parts takes place before each production.

We offer customers a comprehensive application-related service such as advice, calculation, development and sample production for torsion springs, double torsion springs and bent wire parts.

Keywords:

torsion spring, torsion springs, double torsion spring, double torsion springs, bent wire part, bent wire parts

The torsion spring:

Cylindrical torsion springs or also known as torsion springs, helical torsion springs are widely used and versatile machine elements components in the world of mechanics and spring technology.

The structure of a cylindrical torsion spring consists of a wire that is wound in a helical shape around a central axis in even turns.

torsion springs are used to absorb and release a rotating movement, a torque or a force and to guide the movement of the legs.

torsion springs are characterized by the ability to absorb and release deflections, forces or torques around a rotation axis and to guide the rotational movement.

torsion springs usually have a cylindrical spring body on which two legs are arranged.

The legs can be arranged tangentially, radially or axially, whereby each leg can have a different arrangement. Different spring end shapes can be attached to the end of the two legs, e.g. straight leg, hook shape, eyelet shape, round or square.

The terms "torsion spring", "torsion spring" and "torsion spring" refer to the same component.

More detailed information about torsion springs, torsion springs, torsion springs - torsionally resilient wound metal spring ...

The double torsion spring:

Double torsion springs, double torsion springs and double torsion springs are widely used and versatile machine elements in the world of mechanics and spring technology.

The structure of a double torsion spring consists of a wire that is wound in a helical shape in even turns to form two separate spring bodies. The two spring bodies are connected by a wire, which is usually designed as a U-shaped web.

The legs or spring ends of the double torsion springs are usually attached to the outside of the respective spring body. The force or torque is introduced either via the U-shaped web or via the legs. The double torsion spring is usually guided via a mandrel, axle or bolt.

Double torsion springs, double torsion springs and double torsion springs are used to absorb or release a rotating movement, torque or force. Double torsion springs are characterized by the ability to absorb or release deflections, forces or torques around a rotation axis. The legs can be arranged tangentially, radially or axially, whereby each leg can have a different arrangement. Different spring end shapes can be attached to the end of the two legs, e.g. straight leg, hook shape, eyelet shape, round or square.

More detailed information on double torsion springs, double torsion springs and double torsion springs ...

The wire bent part:

In practical use, standardized wire bent parts such as spring rings, snap rings, retaining rings, clips, pins, etc. are found. A paper clip or a staple clip also belongs to the wire bent parts, wire form springs and bent parts.

However, in practical use, non-standardized, individual, application-specific designed wire bent parts are mostly used. Wire form springs and bent parts are used.

The focus is on the function of the component: e.g. securing, protecting, holding, positioning, clamping or springing.

Wire form springs, wire form springs and bent parts made of spring steel wire are important components in various industries and applications. Bent wire parts are special machine elements that usually have springy properties.

They are made into a specific shape by bending wire and offer a variety of advantages in terms of flexibility, cost-effectiveness and functionality.

More detailed information on bent wire parts, wire form springs and bent parts ...